Liquid Metal Epoxy Coating

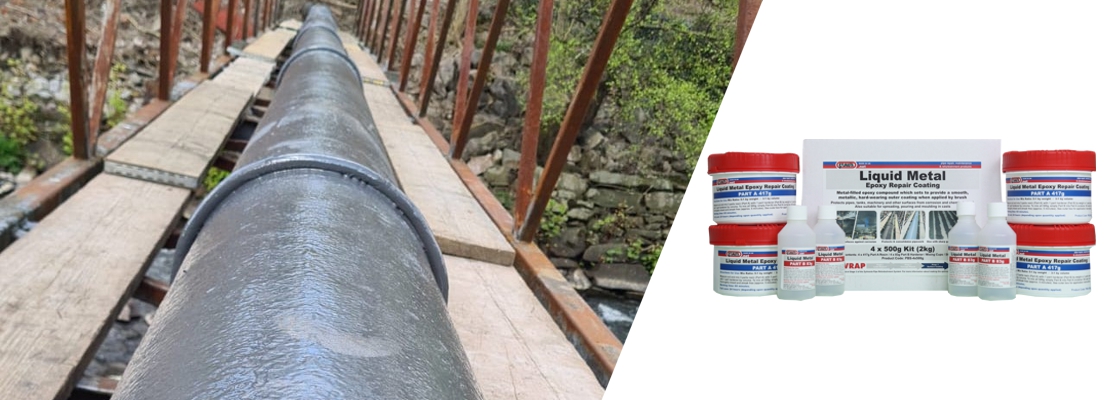

Liquid Metal is a metal-filled epoxy coating brush applied to metal and plastic surfaces. It cures to form a smooth, metallic, hard-wearing outer layer which is resistant to corrosion and chemical attack. In pipe repair applications, Liquid Metal extends the working lifespan of systems by forming a protective external shield around a pipeline.

Coating a pipe with Liquid Metal prevents the original line becoming weakened. Liquid Metal also protects against damage caused by internal corrosion by creating an impermeable membrane around pipework, capable of withstanding future breaches of the line from inside and containing pipe content.

When making a repair with a SylWrap Pipe Repair Bandage, a coating of Liquid Metal added to the pipe before the bandage improves surface adhesion between the pipeline surface and composite wrap.

This subsequently increases the effectiveness of the protective layer provided by the bandage. When applied in conjunction with SylWrap, Liquid Metal can be used as a load-transfer layer providing PCC-2 compliant repairs.

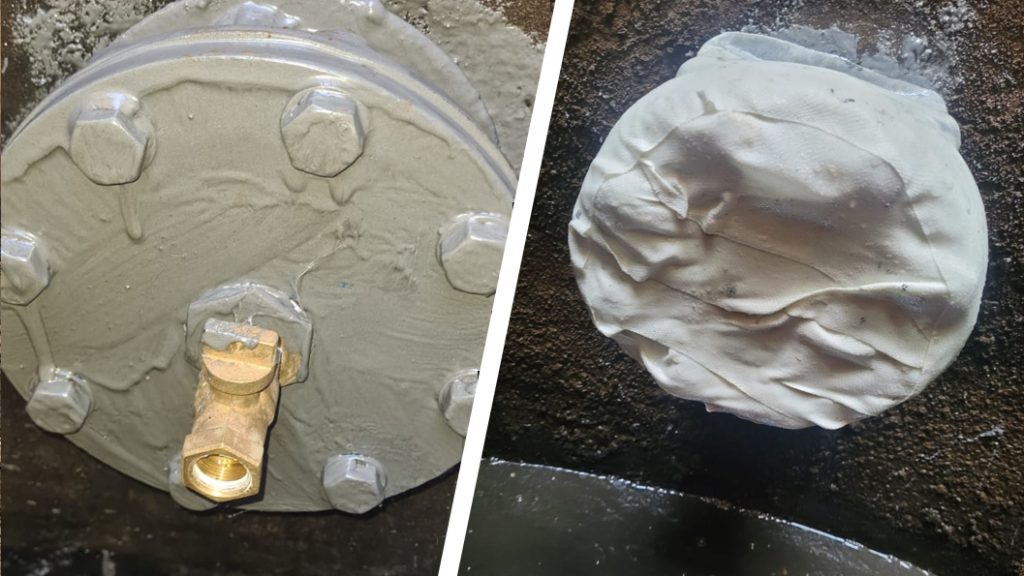

Away from pipe repair, Liquid Metal is used as an adhesive for re-gritting floors and other surfaces, pouring into moulds to create metal casts, and for the maintenance and repair of tanks, pumps, valves, flanges, engines, and impellers. It can be easily machined.

A 90-minute gel time allows for large quantities to be mixed and carefully applied without the threat of premature curing. Because of its work time, Sylmasta recommend Liquid Metal for applications taking place at higher ambient temperatures.

Liquid Metal Epoxy Coating Details

Before applying Liquid Metal, surfaces should be free of paint, rust and grime before being roughened up through either grit blasting or grinding with a coarse wheel or abrasive disk pad.

Full instructions detailing the preparation process can be found on the Technical Data Sheet and are provided with the product.

Liquid Metal should be applied as soon as the preparation procedure is completed. Part A and Part B are mixed at a 3:1 ratio by volume or a 5:1 ratio by weight.

To ease the mixing process, the Liquid Metal Part A container has enough room to dispense all Part B into, enabling it to be applied with a brush straight from the container.

The epoxy is brush applied and each coating should be 0.5-1mm thick. To ensure a pinhole-free coating, at least two coats are needed.

Liquid Metal has a gel time of 90 minutes. The re-coating time between coats is approximately 5–8 hours after applying. A full cure is achieved 24 hours after the final coat.

When adding a SylWrap Bandage in pipe repair applications, the bandage is applied once the coating of Liquid Metal has gelled but remains tacky.

To determine the quantity of Liquid Metal needed for a specific pipe repair application, please go to the Repair Calculator Tab and enter your repair data.

The light consistency of Liquid Metal makes it easy to mix and apply with little sag. It is virtually odourless, with no unpleasant smell, can be easily machined and is temperature resistant to 150°C.

Liquid Metal is temperature resistant to 150°C. For protecting pipework and surfaces exposed to extreme temperatures in excess of 150°C, please see Titanium Supergrade HT Epoxy Paste.

With Liquid Metal not effective underwater, Sylmasta recommend SylWrap CR Corrosion Protection Wrap for the protection of pipes and structures in marine environments.

SylWrap CR is a specialist composite repair wrap infused with highly effective corrosion inhibitors which is applied directly underwater.

Benefits of Liquid Metal

- Easily mixed and applied – just paint onto a surface using a brush

- Increases protection against corrosion and chemicals

- Longer working time allows for complex jobs to be carried out

- Can be easily machined

Applications

- Protection of metal and plastic pipes from chemical attack and external corrosion

- Forming an impermeable membrane to prevent breaches caused by internal corrosion

- Maximising surface contact to composite repair wrap

- Repair and maintenance of pumps, impellers, flanges, water box ends, valves, metal casting, pipe elbows, tanks

- Can be poured into a mould to create metal casts

- Bonding grit to floors and machinery to provide non-slip and non-stick surfaces

- Increases corrosion resistance of metalwork when painted on as a protective coating

- Chocking, filling and levelling machinery and equipment

Technical Data

| Data | |

| Work Time | 90 minutes |

| Re-coat Time | 4-6 hours |

| Full Cure | 24 hours |

| Shore D Hardness | >80 |

| Compressive Strength | 59 MPa |

| Max Service Temp | 150°C |

Product Codes

| Code | Paste Quantity |

| PBS-500g | 500g |

| PBS-4x500g | 2kg (4 x 500g) |

| PBS-2kg | 2kg |

| PBS-5kg | 5kg |

TDS Downloads

Liquid Metal Epoxy Coating Repair Calculator

The below Liquid Metal & Ceramic Brushable Coverage Calculator can be used to determine the quantity of Liquid Metal needed to coat a specific pipe, cylinder or surface area.

Enter the diameter of the pipe or the width of the repair area in millimetres, the length of the repair area and the coating thickness of Liquid Metal to be applied. The wastage percentage is how much Liquid Metal you expect to lose in the application.

Once you have entered your data, the calculator will show the amount of Liquid Metal required in kilograms. If you require further help with an application, please fill in the report form at the bottom of the calculation and a Sylmasta technician will get back to you.

Liquid Metal Epoxy Coating Case Studies

Case Study: Corroded & Leaking Worthington-Simpson Pump Head Repair

Case Study: Repair of Corroded Domestic Water Main Pipe Embedded With Stones

Case Study: Heat Exchanger Water Box Corrosion Protection at Power Plant

Case Study: Corroded 30-Metre Section of Sewer Force Main In Underground Vault Repair

Case Study: Luxury Portable Toilet Trailer Leaking Wastewater Holding Tank Repair

Case Study: Repair of Leaking & Corroded Shared Water Supply Pipe Connected to Eight Cottages

Case Study: Corrosion Protection of 600mm Ductile Pipe & Outlets in Underground Pumping Station

Case Study: 3 Metre Section of Corroded Steel Gas Pipe in CHP System Repair & Refurbishment

Case Study: Capped Pipe Encapsulation in Decommissioned Landfill Drainage System Landfill

Case Study: Permanent Anti Slip Solution to Protect Workers When Standing on Helicopter Skids

Case Study: Repair & Refurbishment of Corroded 20 Metre Long Porth Pipe Bridge

Case Study: Liquid Metal Lays Anti Slip Flooring Surfaces at PepsiCo Plant in Chile

Case Study: Reinforcement of Weakened 22 Degree Cast Iron Pipe Elbows

Liquid Metal Epoxy Coating Videos

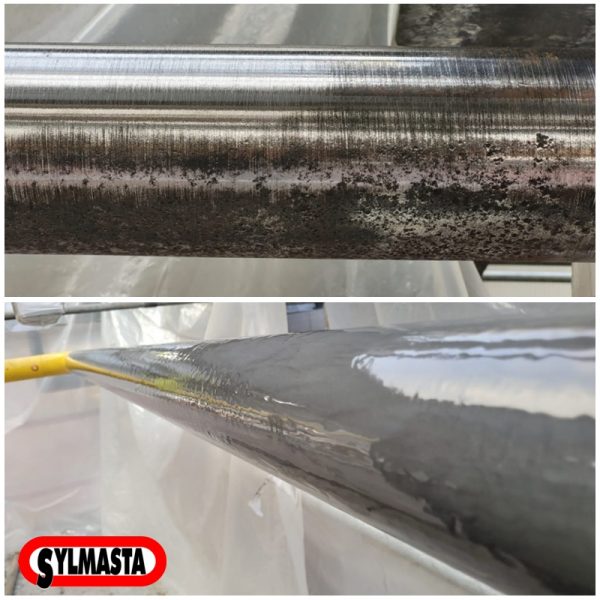

Using Liquid Metal to refurbish and protect metalwork

This demonstration video filmed at Sylmasta HQ shows how Liquid Metal refurbishes rusted metalwork by strengthening the original substrate, as well as protecting equipment and surfaces against future corrosion.

Liquid Metal was applied using a brush to a heavily corroded carbon steel industrial barrel. Cure speed was then increased from the standard 5-8 hours using a hot air gun.

Once set, Liquid Metal formed a new, hard wearing outer surface over the weakened steel – reinforcing the brittle metalwork and acting as a barrier against any further attack.

Please use the form to enquire about the price and availability of

Liquid Metal Epoxy Coating

Related Corrosion Protection Products

SylWrap CR Corrosion Protection Wrap

Pipe repair bandage infused with corrosion inhibitors to further protect pipes in harsh, aggressive environments including marine and underwater against substrate corrosion.

Number of Repairs: One Per Bandage

Work Time: 2–5 minutes

Temperature Resistance: Up to 250°C

Pressure Resistance: Up to 30bar

Titanium Supergrade HT Epoxy Paste

Alloy-filled epoxy paste with very high compressive strength and extreme temperature resistance. It is used for the repair and maintenance of systems operating in environments up to 250ºC and stress-bearing equipment including shafts, keyways and splines.

Work Time: 180 minutes

Functional Cure: 16 hours

Max Service Temp: 250ºC

Ceramic Brushable Epoxy Coating

Ceramic-filled epoxy coating reinforced with silicone carbide for ultimate hardness and an ultra-smooth finish. It protects and seals parts, machinery and surfaces against abrasion and wear, extending system lifespan and improving efficiency by reducing friction.

Work Time: 45 minutes

Re-coat Time: 4-6 hours

Max Service Temp: 150ºC