Epoxy Coating

Epoxy coating is brush applied to surfaces, structures, machines and parts to form a protective layer against abrasion, corrosion, chemical attack, pitting, cavitation and erosion. An expoxy coating protects new parts before they go into service and refurbishes older or worn equipment, extending the lifespan of systems.

Sylmasta manufacture three epoxy coatings all effective on metal, most plastics and wood. They are painted onto surfaces, curing to form a toughened outer shield protecting the original substrate.

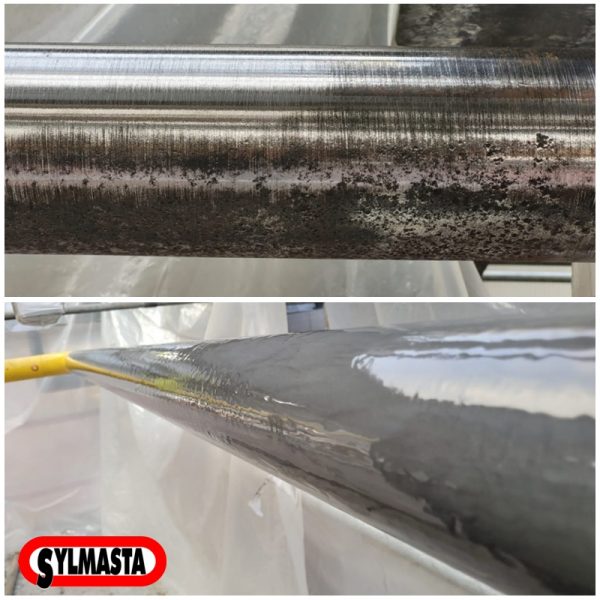

Liquid Metal is metal-filled and most commonly used for pipe repair. It protects against external pipeline damage, internal corrosion and can withstand future breaches of the original line from inside to contain pipe content.

When applied in conjunction with SylWrap Pipe Repair Bandage, Liquid Metal can be used as a load-transfer layer providing PCC-2 compliant repairs. Away from pipe repair, it is pourable into moulds to create metal casts and installs anti slip surfaces by bonding grit to floors.

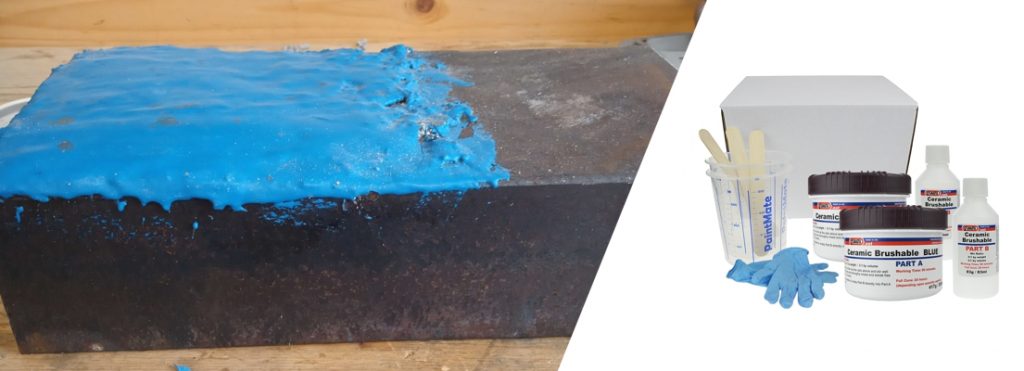

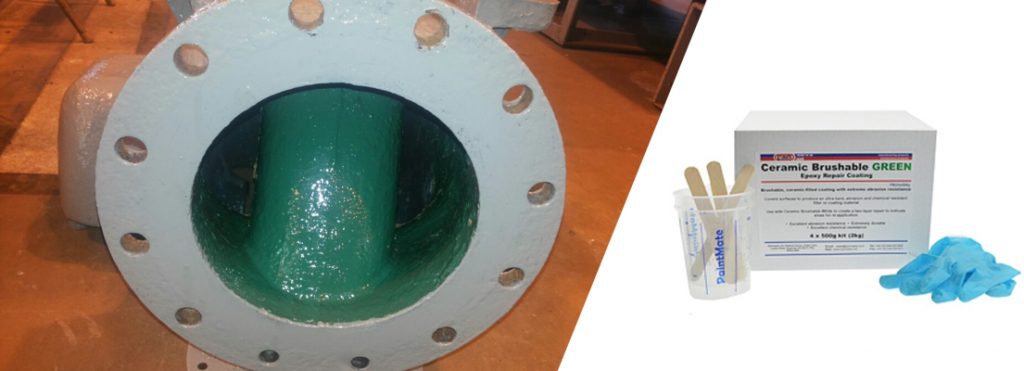

Ceramic Brushable coatings are ceramic-filled and reinforced with silicone carbide. This gives them extra hardness and an ultra-smooth finish. Their toughness enables them to protect and seal parts against abrasion and wear, at the same time as creating low-friction surfaces.

Two colours of Ceramic Brushable are available – blue and green. These can be combined to create a two-layer wear indicator coating. A topcoat of one colour is applied over a base coat of the other. When the base coat shows through, it is an indication that new wear protection measures are needed.

Versatile, metal-filled coating with a wide range of repair, refurbishment and maintenance uses. It offers excellent protection against corrosion and chemical attack, curing to form a protective outer shield around pipework, equipment, machine parts and surfaces.

Work Time: 90 minutes

Re-coat Time: 4-8 hours

Max Service Temp: 150ºC

Ceramic Brushable Blue Epoxy Coating

Blue-coloured, ceramic-filled epoxy coating reinforced with silicone carbide for ultimate hardness and an ultra-smooth finish. It protects and seals against abrasion and wear, extending system lifespan and improving efficiency by reducing friction.

Work Time: 90 minutes (Fast 45 minute version available)

Re-coat Time: 4-8 hours

Max Service Temp: 150ºC

Ceramic Brushable Green Epoxy Coating

Green-coloured, ceramic-filled epoxy coating reinforced with silicone carbide for ultimate hardness and an ultra-smooth finish. It protects and seals against abrasion and wear, extending system lifespan and improving efficiency by reducing friction.

Work Time: 90 minutes (Fast 45 minute version available)

Re-coat Time: 4-8 hours

Max Service Temp: 150ºC