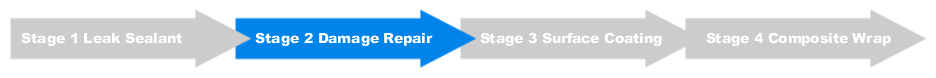

Damage Repair & Pipeline Strengthening:

Sylmasta Pipe Refurbishment System Stage 2

The Damage Repair Stage strengthens any pipe which has been weakened, degraded or suffered external damage caused by corrosion, chemical attack or other environmental factors. Applying an epoxy compound to the exterior surface of a pipeline restores integrity and surface profile, rebuilds outer wall thickness and brings a line back up to specification.

Where pitting or other pipe damage is present, epoxies fill in and repair the damage. They also provide full contact and load spreading between the pipe and the composite wrap (added at Stage 4 of the Sylmasta Pie Refurbishment System), further strengthening the repair.

Industrial Metal Epoxy Paste and Titanium HT Supergrade Epoxy Paste are used for the strengthening of large areas of metal or plastic pipeline. They are spread over the weakened section with a hand tool, curing to reinforce the original line.

Epoxy putties are applied by hand. Sylmasta AB Original Epoxy Putty rebuilds large areas of damage, makes underwater repairs and can be used as a sacrificial layer in chemically aggressive environments. Its two-hour work time allows more careful application without the threat of premature curing.

For faster repairs of large areas, Sylmasta AB Rapid has a 5-minute work time. 114g Superfast Epoxy Putty Sticks quickly rebuild smaller areas of damage.

Industrial Metal has been independently tested to BS 6920 standard. When used with a SylWrap Pipe Repair Bandage, it is certified to British standards as safe to use with potable water. Superfast Steel and Superfast Aqua PW have WRAS approval for making repairs to pipes carrying drinking.

Metal-filled epoxy paste applied with a putty knife to rebuild large areas of damaged metal and plastic pipes. It makes BS 6920 compliant repairs when used with SylWrap Bandage..

Number of Repairs: Multiple

Work Time: 60 Minutes

Temperature Resistance: Up to 130°C

Titanium Supergrade HT Epoxy Paste

Alloy-reinforced epoxy paste for rebuilding large areas of pipework exposed to temperatures up to 250°C. It is applied with a putty knife or hand tool and has a three-hour work time.

Number of Repairs: Multiple

Work Time: 180 Minutes

Temperature Resistance: Up to 250°C

Sylmasta AB Original Epoxy Putty Stick

Ceramic-filled epoxy putty with a two-hour work time hand applied to rebuild pipes of all materials. It makes underwater repairs and will act as a sacrificial layer in chemically aggressive environments.

Number of Repairs: Multiple

Work Time: 120 minutes

Temperature Resistance: Up to 300ºC

Sylmasta AB Rapid 5 Minute Epoxy Putty

Combines the cure speed of 114g Superfast Epoxy Putty Sticks with the super-strength formulation of AB Original. It is hand applied, rebuilds pipes of all materials and offers good chemical resistance.

Number of Repairs: Multiple

Work Time: 5 minutes

Temperature Resistance: Up to 150ºC

Superfast Steel Epoxy Putty Stick

Steel-filled, WRAS approved epoxy putty in a ready-to-use 114g stick. A rapid cure time allows smaller sections of damaged steel and other ferrous pipes to be rebuilt in under five minutes.

Number of Repairs: Multiple

Work Time: 3 Minutes

Temperature Resistance: Up to 150ºC

Superfast Aqua PW Epoxy Putty Stick

WRAS approved epoxy putty with a specialist formulation enabling very high wet surface adhesion. It comes in a ready-to-use 114g stick and rebuilds small areas of damage on underwater pipes.

Number of Repairs: Multiple

Work Time: 3 Minutes

Temperature Resistance: Up to 150ºC

Superfast Titanium Epoxy Putty Stick

Titanium-filled epoxy putty specifically formulated for use with high temperature pipework up to 280ºC. It comes in a ready-to-use 114g stick and rebuilds small areas of damage on pipes and tanks.

Number of Repairs: Multiple

Work Time: 90 minutes

Temperature Resistance: Up to 280ºC