Sylmasta Pipe Refurbishment System

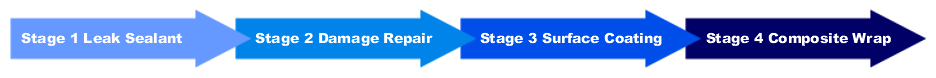

The Sylmasta Pipe Refurbishment System is a four-stage process which is designed for pipeline repair, refurbishment, strengthening, and protection in any given scenario. Repairs go beyond what is possible with the SylWrap Leak Repair range of products, providing complex solutions for global pipeline operators and critical infrastructure providers.

Large sections of heavy pipeline damage can be repaired and rebuilt using the Sylmasta Pipe Refurbishment System. It strengthens and reinforces pipelines in the most challenging of environments, including underwater.

At each of the four stages of the process, the product most relevant to the specific application is selected. When used in conjunction, these products enable the optimum repair to be carried out, providing a cost-effective and less disruptive alternative to pipeline replacement.

Some applications may require further specialist solutions. In such instances, Sylmasta can formulate and supply specialist materials, such as composite epoxy resins for applications where very high chemical or temperature resistance is required.

To help select the correct products and quantities for a specific application, Sylmasta have created a Pipe Refurbishment Calculator available at the bottom of this page. Simply input your repair data to see Sylmasta recommendations for your repair.

If you do not see a product at any stage of the process which appears suitable for your repair, then please contact Sylmasta and a technician will be happy to advise.

Stage 1: Leak Sealant

When a pipe is leaking and needs to be sealed, the leak sealant acts as the initial layer of repair. Self-fusing silicone tape seals live leaks, and epoxy putties fill cracks where pressure can be isolated. If there is no leak, this stage of the process is skipped.

Stage 2: Damage Repair

Damage repair products restore surface profile by rebuilding and strengthening areas of pipeline which have degraded or weakened. They also provide full contact and load spreading between the pipe and the composite layer applied at Stage 4.

Stage 3: Surface Coating

An epoxy surface coating provides an additional layer of external protection from corrosion and chemical attack, forming an impermeable membrane around a pipe. It also increases adhesion to maximise surface contact with the composite layer.

Stage 4: Composite Wrap

Refurbishment is completed using a composite wrap to provide a rock-hard, impact resistant shell over the repair. The composite layer further protects pipelines, extends the lifespan of systems, and increases hoop strength and pressure resistance.

The Sylmasta Pipe Refurbishment Calculator

The following calculator app can help determine the most suitable product at each stage of the Sylmasta Pipe Refurbishment System. Start by selecting the Sylmasta Pipe Refurbishment System – Comprehensive Calculator tab. Then enter the diameter of the pipe, the length of pipework to be repaired, the pressure the line operates under and the required safety factor.

The safety factor is a multiple to include a margin of safety. For example, if pipe pressure is 5 bar and you want a safety factor of two, the calculator will formulate a repair capable of withstanding 10 bar.

Filling in the requested information over whether the pipe is leaking, requires surface damage repair and if a protective coating against corrosion is wanted will return each product recommended and the quantity required.

For stage four, the calculator will show the recommended size of SylWrap Pipe Repair Bandage to complete the application. Changing the SylWrap size will calculate the number of bandages of that particular size needed to complete the repair.