Case Study: Protection of Wooden Entrance Gate at an Estate in Scotland Against Rot

After a storm destroyed an entrance gate at an estate in Scotland, robust replacements were fabricated with wooden slats attached to a steel frame. AB Original Epoxy Putty was used to create a bevelled edge at the base of the gate frame where rainwater could otherwise pool, offering protection against rot to the bottom of the wood slats.

Case Study Overview

Site Country estate

Location Scotland

Repair Type Rot protection

Defect Wooden slats on entrance gate with potential to be rotted by static water

Repair Products

Sylmasta AB Original Epoxy Putty

Case Study PDF

Case Study Details

The estate was located in beautiful open countryside. When Storm Arwen brought wind gusts of up to 100mph to Scotland in November 2021, the wooden gates were an easy victim to the violent weather and subsequently became damaged.

In response, the estate decided more robust gates were needed to withstand future storms. A heavy steel frame was constructed for each gate with wooden slats attached to the frame via stainless steel self-tapping screws, providing a much stronger structure.

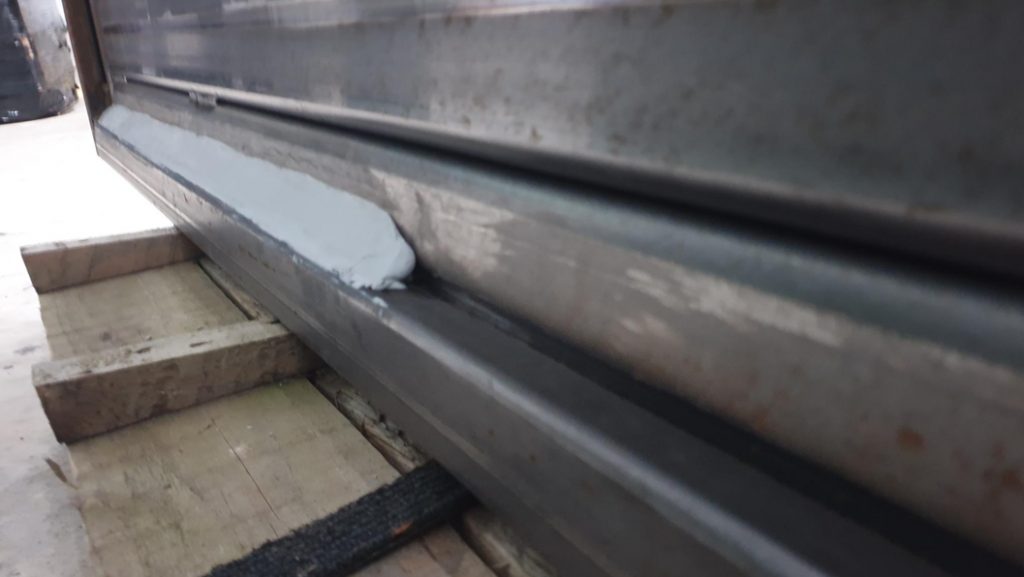

One problem was identified during the construction of the new gates – the potential for rainwater to gather in a groove at the base of the frame. Static water left here would have no means of escape other than evaporation. Where this water came into contact with the wooden slats, it would eventually lead to rotting of the bottom of the slats.

To overcome this, the estate had the ingenious idea of creating a bevelled edge using a waterproof epoxy putty between the base and the frame behind it. Water would be diverted onto the ground instead of pooling at the bottom of the frame – offering protection to the wood gate against rot.

Sylmasta AB Original Epoxy Putty was chosen for the application because of its waterproof qualities and two-hour work time, offering long enough for the putty to be carefully shaped and formed into the shape of a bevelled edge before curing off.

AB Original was mixed by hand. The putty was pushed onto the frame, easily adhering to the steel before being moulded into the required bevel. The bottom of each slat had been similarly bevelled, leaving a 5mm gap separating the wood and the putty.

Once set, AB Original provided an ultra-smooth run off. Rainwater would now drip down this run off, through the gap between putty and slats and onto the driveway below.

The steel frame, wooden slats and epoxy putty were then coated in a protective paint. The paint was a beige colour, disguising the steel frame and the epoxy putty to make the entire structure appear uniformly made of wood.

Since being installed, the new gates have proven to be far more robust against the extreme Scottish weather. The application constituted a fine piece of engineering involving some out-of-the-box thinking which should last a very long time.

Products Used

AB Original Epoxy Putty

Epoxy putty with long work time for shaping without the threat of premature curing

Related Case Studies

Case Study: Rotted Bay Sash Window Frame Undergoes Stabilisation, Repair & Restoration

Case Study: Restoration of Clan MacGregor Dalmally Burial Stones Dated 1390-1528

Case Study: Reassembly & Repair of Composite Stone Water Fountain Cracked into Pieces

Case Study: Classical Composite Order Column Restoration at Former Cinema Built in 1920s

Case Study: Luxury Portable Toilet Trailer Leaking Wastewater Holding Tank Repair

Case Study: Leaking Concrete Flood Defence Wall Repair at Multimillion Pound Dam in Scotland

Case Study: Rotted Wood Beam Repair in Renovation of Welsh Home

Case Study: Pipe Joints Sealed in Cast Iron Rainwater Stack Repair at London Office Block

If you have an application you would like to enquire about, please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com