Case Study: ‘Impossible’ Repair of a 900mm Water Main Flange Leak in an Underground Chamber

Water escaping multiple cracks around a stub flange on a 900mm steel water main had flooded an underground chamber and been considered impossible to repair by a water company in Malaysia. That was until a local engineering team accompanied by Sylmasta spent two days on-site.

Case Study Overview

Site Underground water main

Location Malaysia

Repair Type No pressure pipe repair

Defect Multiple cracks in 900mm steel water main around flange

Repair Products

Superfast Steel Epoxy Putty

Case Study PDF

Case Study Details

Heavy corrosion had caused numerous cracks to appear on the 900mm steel pipe around a stub flange. The leak point was located in an underground chamber, which had subsequently filled with water escaping the pipe at high pressure.

Accessing the pipe was difficult even before the flooding of the chamber. A repair clamp could not be fitted because of the flange, and the main was so close to the ground that there was insufficient room for pipe repair tapes or bandages to be wrapped around the pipe.

There was no visible means of isolating the main either, meaning that pressure could not be turned off or reduced.

Replacing the damaged section would have involved excavating the chamber and shutting down the main for a prolonged period, something not considered an option by the water company operating the system.

As a result, repairing the underground pipe leak had been considered impossible. It had been allowed to leak unabated since the problem was discovered, save for a few cursory checks and the pumping out of water when flood levels became dangerously high.

That was until an engineering team and a technician from Sylmasta arrived on site, who were determined to formulate either a method for repairing the main or a means of substantially reducing the amount of water being lost.

Before any repair could be attempted, water had to be pumped out of the chamber. Once this had been done, an engineer accessed the pipe and hammered a series of plastic plugs into the larger cracks along the flange.

The plugs reduced the amount of water escaping from the pipe enough for a proper inspection to take place. The engineer in the chamber then spotted a previously unknown stop valve a little further along the pipe.

They were able to reach the stop valve, preventing flow into the leak area. With pressure now turned off, it meant that Superfast Steel Epoxy Putty could be used to attempt to permanently seal the cracks in the main.

Superfast Steel has a fast, 10 minute work time and comes in an easy-to-use 114g stick format requiring no measuring out of Part A or Part B. Numerous sticks had to be used in the application because of the size of the repair.

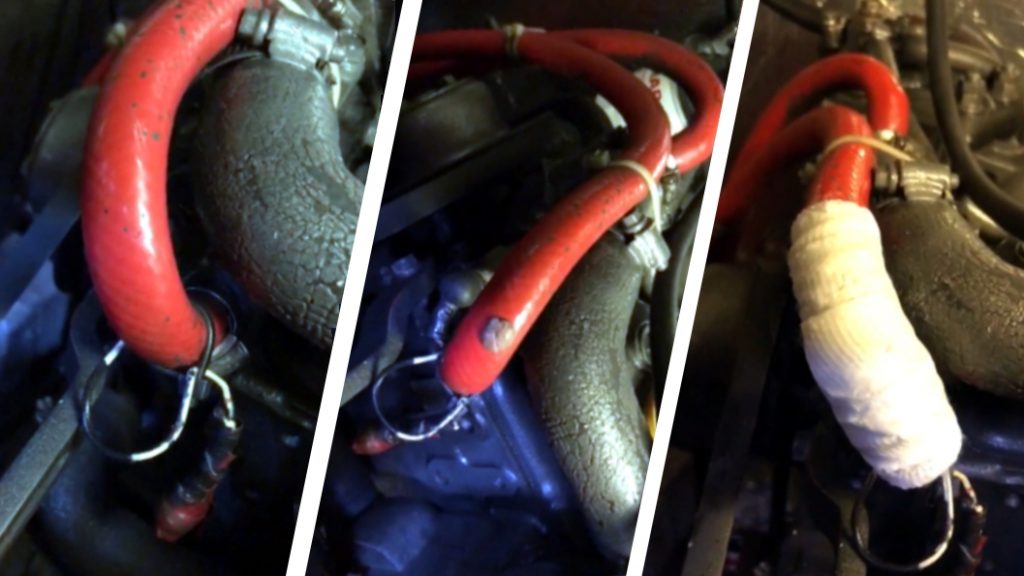

Each stick was kneaded by hand. Whilst soft, the putty was pushed into visible holes in the pipe where it hardened, filling the crack. Superfast Steel was also used to seal the flange and as a means of permanently fixing the rubber plugs in place.

Because of the diameter of the pipe and the size of the damage area, it took over an hour to apply the necessary Superfast Steel. With flow isolated, it was difficult to tell whether all the leaks in the pipe had been found and sealed.

Even after pressure was restored, it was still hard to identify remaining problem areas. As a result, the maintenance team decided to return 24 hours later to check the effectiveness of the repair.

Unfortunately, this inspection revealed the main was leaking again, although nowhere near as seriously as before. There were several small leak areas which had not been suitably arrested the previous day, alongside a larger jet of water escaping from a gap between the flange and the pipe.

Further Superfast Steel was used to seal the smaller leak areas. The epoxy putty was worked into a sausage shape and pushed into the remaining cracks in the pipe.

For the larger leak, the engineering team leader hit upon the idea of fixing a valve fitting in place using more Superfast Steel. The water trying to escape the main would be channelled towards this valve. A tap would be fitted and closed, sealing the pipe shut.

Tapping off the main ended up being a success, much to the delight of the water company and the engineering team.

It may have taken two days, but the ‘impossible’ Malaysia water main repair had been completed, reducing the levels of water being lost and preventing any further flooding of the chamber.

Products Used

Superfast Steel

Fast working steel epoxy putty used to seal cracks in pipes and for permanent bonding

Related Case Studies

Case Study: Hospital Maintenance Team Seal 80mm Diameter Hole in Cast Iron Wastewater Drain Pipe

Case Study: Corroded & Leaking Worthington-Simpson Pump Head Repair

Case Study: Repair of Underground Clay Drainage Pipe Cracked During Building Work

Case Study: Boat Owner Repairs Pinhole Leak in Rubber Hose Connected to Engine

Case Study: External Surface Damage Repair to Restore Integrity of 400mm GRP Pipe

Case Study: Leaking Hydrogen Line Pipe Repair at Power Station in Puerto Rico

Case Study: Superfast Steel Epoxy Putty Used to Fix Rust Holes on a Classic Car

Case Study: Repair of a Leaking 150mm Steel 90 Degree Elbow Bend at a Quarry Wash Plant

Case Study: Repair of a Cracked 90-year-old 70mm Malleable Iron Water Supply Pipe

Case Study: Magic Corner Kitchen Unit Repair Saves Over £200 in Replacement Costs

Case Study: 19th Century Lantern Restoration Using Superfast Steel Epoxy Putty

Case Study: Emergency Repair of Hospital 300mm Air Conditioning Pipe on Hottest Day of June

Case Study: Repair and Reconnection of a Ruptured 20bar Cast Iron Water Supply Pipe

Case Study: Leaking Cast Iron Wastewater Pipe Repair at a London Hotel

If you have an application you would like to enquire about, please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com