Case Study: Water Treatment Plant in Puerto Rico Repair Worn Pump Extracting from a Well

Sylmasta provide a long-term repair solution for a water treatment plant in Puerto Rico, where a pump extracting groundwater from an underground well had become heavily worn due to minerals and sediment in the water. Ceramic Brushable Green created a reinforced lining 8mm thick around the pump, rebuilding the weakened metalwork.

Case Study Overview

Site Water treatment plant

Location Puerto Rico

Repair Type Damage repair

Defect Pump left heavily worn by extraction of groundwater from a well

Repair Products

Ceramic Brushable Epoxy Coating

Case Study PDF

Case Study Details

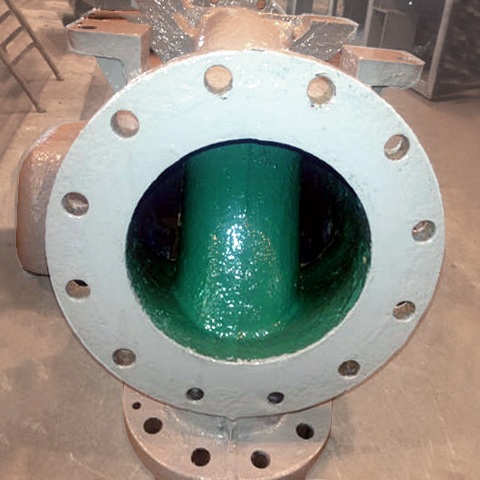

The large water pump was used by the water treatment plant to extract water from a well. The water was then distributed around the entire site for various purposes, making the pump central to operations.

This natural groundwater contained minerals, sediments and impurities which caused deterioration to the pump. Over time, the pump became so worn and degraded that there was a substantial risk of bursting.

A burst would have been a disaster for the plant. Operations would have needed to be shut down and a replacement pump fitted. This would have been a costly and time-consuming exercise, potentially involving the fabrication of a new pump and its shipping to Puerto Rico.

Before the water well pump reached the stage whereby it needed to be replaced, the treatment plant decided to repair and reinforce the system using a hard-wearing, abrasion resistant coating.

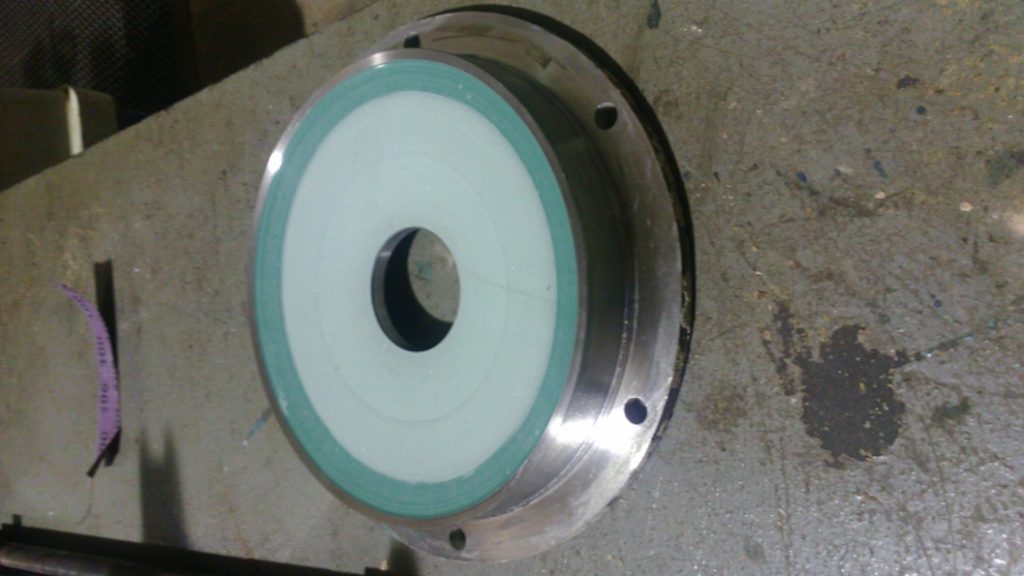

Ceramic Brushable Green Epoxy Coating was used for the application. Ceramic Brushable is reinforced with silicone carbide, giving it a toughened, ultra-smooth finish.

It is painted onto surfaces which have suffered heavy damage or been weakened by corrosion and abrasion, restoring their strength and protecting the original part from further damage.

The two parts of the epoxy coating were mixed in the prescribed ratios and then brushed onto the pump. The 90 minute gel time of Ceramic Brushable enabled more epoxy to be mixed and applied without the threat of premature curing.

Four coatings were used, each between 1mm and 2mm thick. This built up a substantial, reinforced shell around the worn pump to restore the weakened metalwork to its original thickness.

With a recoat time of around four hours, it took two days to complete the repair. The application took place over night whilst the site was shut down to limit disruption and the cost was insignificant compared to fitting a new pump.

The treatment plant now monitor the pump on a regular basis for future wear caused by corrosion and erosion. When there are concerns that it is becoming too weak, further coatings of Ceramic Brushable are added to restore integrity to the pump.

Speaking about the process, the maintenance manager at the plant said: “The pump deteriorates very soon but coating it in Ceramic Brushable helps a lot.” In this way, Sylmasta have provided a cost-effective and long-term solution.

Products Used

Ceramic Brushable

Epoxy coating filled with silicon-carbide which creates a tough surface around metalwork

Related Case Studies

Case Study: Landscaping Materials Company Repair & Protect Warehouse Metal Pallet Slats

Case Study: Copper Mine Repair Pump Housing Heavily Damaged By River Water Extraction

Case Study: Power Station Repair Extensive Damage to Alloy 20 Pump Lid Caused by Impeller

If you have an application you would like to enquire about, please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com