Case Study: Power Station Repair Extensive Damage to Alloy 20 Pump Lid Caused by Impeller

Keeping a lid on the cost of repair for a power station treatment plant pump in Puerto Rico

A power station in Puerto Rico repair a treatment plant pump lid made from Alloy 20 which would have cost $4000 to replace after it suffered extensive damage when an impeller fell out of place.

Case Study Data

Site

Power station treatment plant

Location

Puerto Rico

Repair Type

Damage repair

Defect

Gouged and scratched Alloy 20 pump lid

Products Used

Ceramic Brushable Green

Brushable epoxy coating used to repair surface damage and offer greater protection of the Alloy 20 pump lid

Case Study PDF

Case Study Data

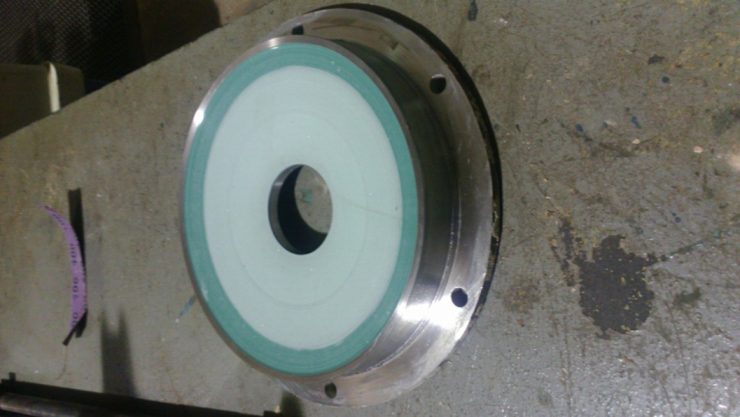

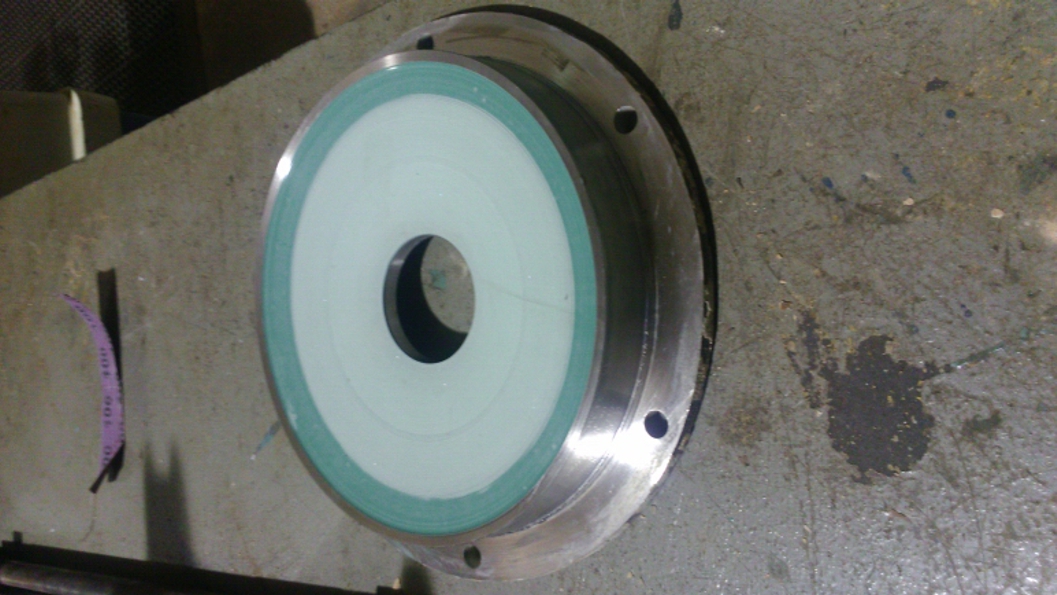

The pump lid came from a mud pool at the power station treatment plant. It was 500mm in diameter and made from Alloy 20 (nickel-chromium-molybdenum stainless steel) for its high chemical and corrosion resistance.

Extensive damage had been caused when an impeller blade came out of place and fell directly onto the lid, leaving numerous scratches and several very deep gouges across the surface.

A replacement lid would have cost $4000 and required shipping to Puerto Rico, potentially leaving the pump out of service for a significant amount of time and causing disruption to operations.

The power station instead used Ceramic Brushable Green Epoxy Coating to repair the pump lid. Ceramic Brushable is reinforced with silicone carbide, giving it a toughened, ultra-smooth finish.

It is painted onto surfaces which have suffered heavy surface damage or been weakened by corrosion and abrasion, restoring their strength and protecting the original part from further deterioration.

The lid was removed from the pump. Part A and Part B of Ceramic Brushable Green were mixed and then applied via brush. The first few coatings were used to repair the damage by filling in the gouges and scratches, found mostly in the centre of the lid.

This was followed by additional layers being added across the entire 500mm area, creating a new reinforced surface over the original Alloy 20 to offer protection to the lid.

Once the final coating of Ceramic Brushable Green had begun to harden, the lid was turned on a lathe to finish it. The two colour tones on the complete repair show where the lid is angled towards the edge.

After a full cure had been achieved, the lid was fitted back in place and the water treatment plant could return to full service. The power station were extremely pleased with the application as it prevented a costly replacement which would have resulted in downtime at the site.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com