How to Repair a Damaged, Worn or Scored Shaft

The repair of a damaged, worn or scored shaft is made using Titanium Supergrade HT Epoxy Paste. Titanium Supergrade has been specifically formulated for high compressive strength and extreme temperature resistance, making it suitable for the repair and maintenance of stress-bearing equipment subjected to heat up to 250ºC.

1) Surface Preparation / Undercut

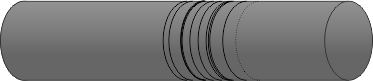

Because a shaft repair requires machining, surface preparation is different to other metal repairs. The damaged area is undercut using a lathe. Shafts up to 25mm diameter are undercut to 1.5mm. Shafts between 25mm and 75mm should be undercut to 3mm.

If the shaft is already worn to the recommended depth, undercutting is not necessary. The ends of the damaged section should be dovetailed to serve as a guide to the repair area and lock Titanium Supergrade HT into place.

2) Roughen Surface to Improve Adhesion

The undercutting process is finished by roughening up the surface of the shaft for better adhesion between the metalwork and Titanium Supergrade HT.

A rough cut surface or gramophone pattern is machined onto the shaft based on diameter. The larger the shaft, the deeper the threads. Once machined, use Sylmasta Non-Flammable Degreaser to thoroughly clean the metalwork.

3) Apply Titanium Supergrade HT Epoxy Paste

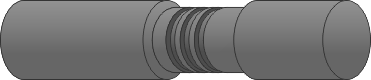

Follow the mixing instructions provided with Titanium Supergrade HT. Once mixed, apply a thin layer of epoxy paste to the repair area using a putty knife. Force the paste into the bottom of the threads.

Next, turn the shaft at a very low speed. Continue to apply Titanium Supergrade HT until the entire worn area has been filled with epoxy paste, up to and then above the level of the original shaft surface.

4) Machine Epoxy Paste to Original Shaft Dimensions

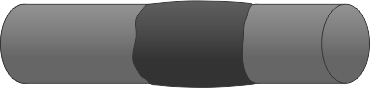

After application of Titanium Supergrade HT, the repair is machined back to meet the original dimensions of the shaft. The most effective way to do this is via lathe with a top rake, side clearance and front clearance of 3º.

Lathe speed should be 46 metres per minute, a roughing feed rate of 0.64mm per revolution and a finishing feed rate of 0.25mm per revolution.

5) Polish Repair

To cut dry the shaft repair, use carbide or high speed steel bits.

If polishing of the shaft repair is required, only use wetted 400 to 600 grit emery paper.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com

Sylmasta Products for Damaged, Worn and Scorn Shaft Repairs

Titanium Supergrade HT Epoxy Paste

Alloy-filled epoxy paste with very high compressive strength and extreme temperature resistance. It is used for the repair and maintenance of systems operating in environments up to 250ºC and stress-bearing equipment including shafts, keyways and splines.

Work Time: 180 minutes

Functional Cure: 16 hours

Max Service Temp: 250ºC