How to Repair a Damaged Keyway

Shaft keyways become worn and oversized by the constant pressure of starting and stopping, leading to stress on couplings, vibrations and misalignment. The repair and rebuild of a damaged keyway is made using Titanium Supergrade HT Epoxy Paste because of its extremely high compressive strength.

1) Surface preparation

Surfaces must be free from grease, paint, rust and grime. Cleaning and roughening the surface will optimise adhesion with the epoxy paste. Use a file or rotary grinding tool to roughen and then clean using Sylmasta Non-Flammable Degreaser.

Full instructions detailing the preparation process are provided with Titanium Supergrade HT and can be found on the product TDS.

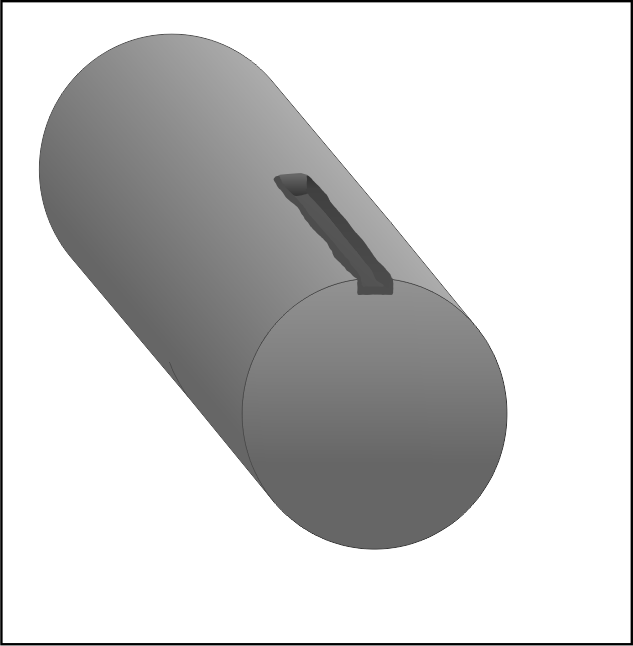

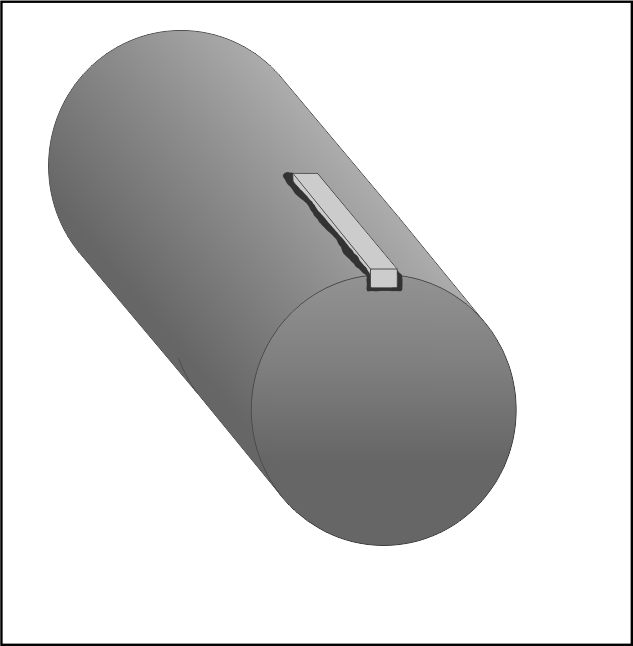

2) Apply Titanium Supergrade HT Epoxy Paste to keyway

Follow the mixing instructions provided with Titanium Supergrade HT. Once mixed, fill the keyway undergoing repair with epoxy paste using a putty knife or spatula.

A thin layer of Titanium Supergrade HT is used at the bottom of the keyway with a thicker layer on the side walls. This ensures that when the key is inserted, it does not rise too high above the keyway.

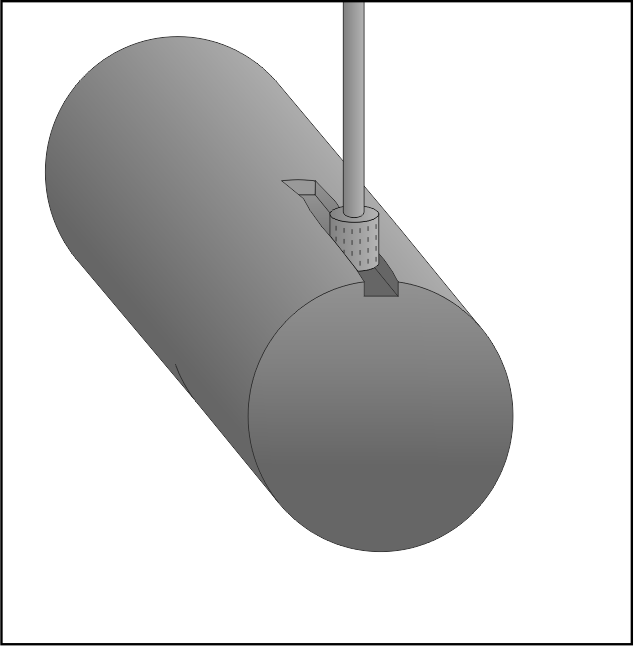

3) Coat key with Release Agent and insert into keyway

Apply Sylmasta Non-Flammable Release Agent over the key and hub to prevent them being bonded with the keyway during the curing process of Titanium Supergrade HT.

Once the key has been coated in Release Agent, install it into the keyway. Immediately scrape away all excess epoxy paste from the side of the keyway and any overspill on the shaft.

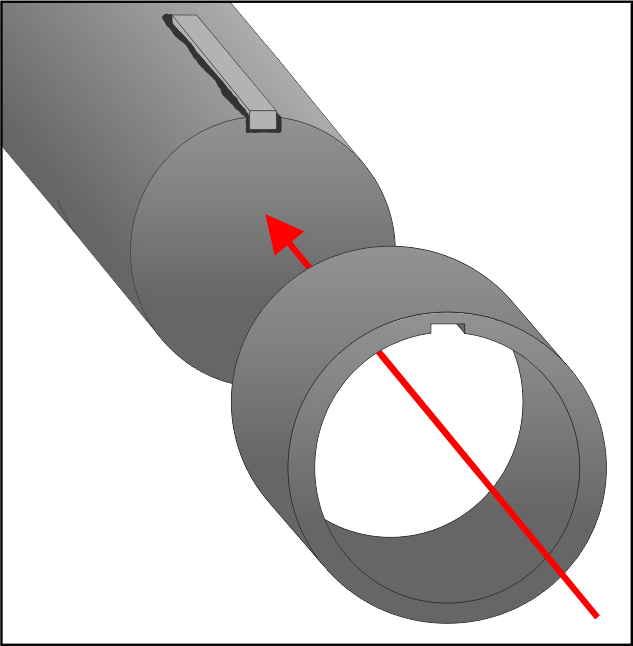

4) Obtain proper alignment

As soon as the shaft has been cleaned of epoxy paste overspill, align the key with the keyway in the hub. The shaft is then inserted into the hub to obtain proper alignment.

Leave the shaft and hub assembled until Titanium Supergrade HT achieves a full cure. This will normally be 24 hours, depending on ambient temperature. The key is then removed, leaving behind a rebuilt keyway.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com

Sylmasta Products for Damaged Keyway Repair

Titanium Supergrade HT Epoxy Paste

Alloy-filled epoxy paste with very high compressive strength and extreme temperature resistance. It is used for the repair and maintenance of systems operating in environments up to 250ºC and stress-bearing equipment including shafts, keyways and splines.

Work Time: 180 minutes

Functional Cure: 16 hours

Max Service Temp: 250ºC