WearShield Rapid 5 Minute Alumina Filled Epoxy Paste

WearShield Rapid is an alumina-filled epoxy repair paste with a 5-minute work time. It offers the ultimate protection to equipment, machinery and surfaces from all types of impact damage by forming an alumina-reinforced, hardened shell up to 6mm thick. The fast work time of WearShield Rapid allows systems to be put back into use within a few hours.

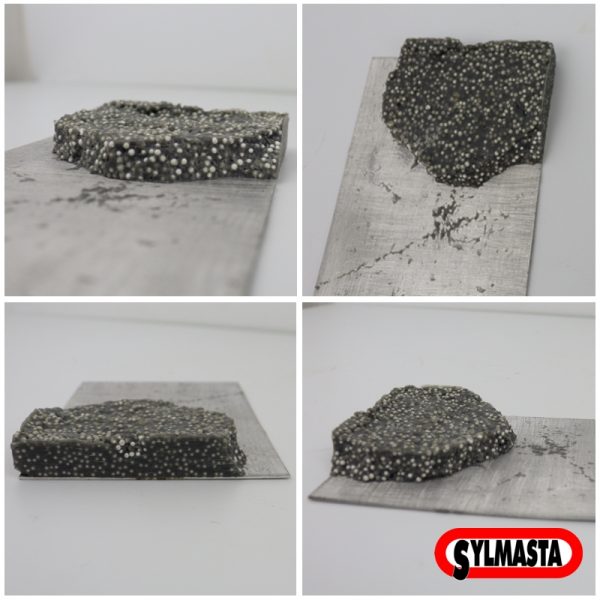

The dense alumina bead structure and high resin content of WearShield Rapid offer extreme resistance against impact, wear, corrosion and chemical attack for systems subjected to intense processes.

WearShield Rapid achieves a functional cure in 45 minutes and a full cure in three hours, reducing disruption and downtime. It was originally formulated for the tough requirements of the South America mining industry, with expansion since into power plants, quarries, mills and other industries.

It protects a range of processing and plant equipment including ash handling systems, scrubbers, silos, chutes, mineral nozzles, agglomerator drums, trunions and metal castings. It can be applied to metal, wood and most plastics.

WearShield Rapid also repairs heavy damage and rebuilds existing systems already suffering from impact damage by creating a new, hardened surface.

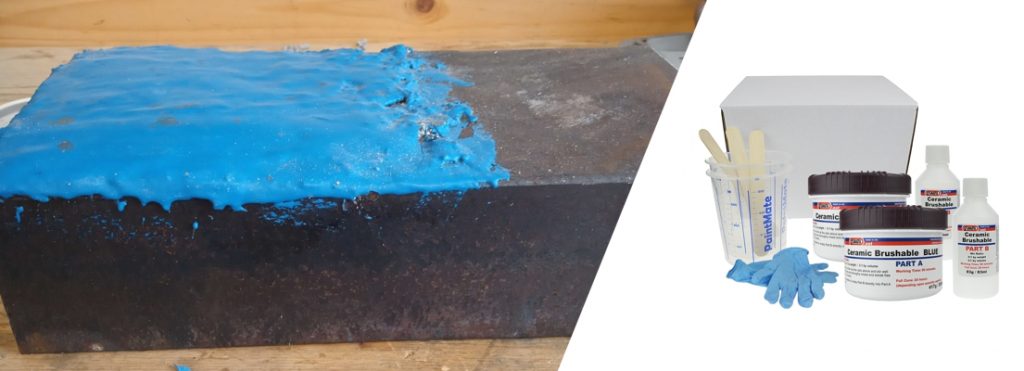

It sets to a dark grey colour and the alumina beads are visible in the cured material. Once cured, WearShield Rapid can be top coated with Ceramic Brushable Blue Epoxy Coating to create an ultra-smooth repair, further reducing abrasion damage and making clean up more effective.

WearShield Rapid 5 Minute Epoxy Paste Details

Before applying WearShield Rapid, surfaces should be free of paint, rust and grime. The substrate should then be roughened up through either grit blasting or grinding with a coarse wheel or abrasive disk pad.

Full instructions detailing the preparation process can be found on the Technical Data Sheet and are provided with the product.

WearShield Rapid should be applied as soon as the preparation procedure is completed. Part A and Part B are mixed together in equal quantities by weight or volume until streak free and uniform in colour.

The epoxy paste is then spread over the area requiring protection using a putty knife. WearShield Rapid should be pushed in firmly to ensure maximum contact and to avoid trapping air between the paste and the surface.

WearShield Rapid is built up until the desired thickness is achieved, recommended to be at least 6mm. A functional cure is achieved in 45 minutes and full cure in three hours. WearShield Rapid is temperature resistant to 105°C.

The light consistency makes WearShield Rapid easier to mix than stiff and heavy traditional epoxy pastes. It is thixotropic, meaning it will not sag.

For an impact resistant resistant epoxy paste filled with alumina beads but a slower work than the five minutes of WearShield Rapid, please see WearShield Standard.

It comes with a work time of up to one hour, enabling more paste to be mixed and carefully applied without the threat of premature curing. Sylmasta recommend the standard grade of WearShield for use at higher ambient temperatures.

Benefits of WearShield Rapid 5 Minute Epoxy Paste

- Alumina filled for extreme impact, abrasion and wear resistance

- Fast working for rapid application, minimising disruption and equipment downtime

- Effective on metal, wood and most plastics

- Increases resistance against corrosion and chemical attack

Applications

- Protecting equipment from wear, impact and abrasion in mines, quarries and mills

- Repairing heavy damage to ash handling systems, scrubbers, silos, chutes, mills and metal castings

- Coating mineral nozzles, mill trunnions, agglomerator drums and mineral screens

- Protecting machinery, parts and surfaces against corrosion and chemical attack

Technical Data

| Data | |

| Work Time | 5 minutes |

| Functional Cure | 45 minutes |

| Full Cure | 3 hours |

| Shore D Hardness | 89 |

| Max Service Temp | 105°C |

Product Codes

| Code | Paste Quantity |

| PWEAR-RAPID-3kg | 3kg |

| PWEAR-RAPID-13kg | 13kg |

TDS Downloads

WearShield Rapid 5 Minute Epoxy Paste Videos

How to increase wear resistance with WearShield Impact Resistant Epoxy

See how WearShield increases impact and wear resistance by creating an alumina reinforced protective layer over equipment, machinery, parts and surfaces. This demonstration involved the application process of WearShield to a demo piece, an abrasion and impact test, followed by overcoating with Ceramic Brushable Blue to provide an ultra-smooth layer to the repair.

Please use the form to enquire about the price and availability of

WearShield Rapid Alumina Filled Epoxy Paste

Related Wear Protection Products

Ceramic Brushable Blue Epoxy Coating

Blue-coloured, ceramic-filled epoxy coating reinforced with silicone carbide for ultimate hardness and an ultra-smooth finish. It protects and seals against abrasion and wear, extending system lifespan and improving efficiency by reducing friction.

Work Time: 90 minutes (Fast 45 minute version available)

Re-coat Time: 4-8 hours

Max Service Temp: 150ºC

WearShield Impact Resistant Epoxy Paste

Alumina bead-filled epoxy for ultimate hardness and protection against all types of wear and impact damage. It is applied to equipment, machinery and surfaces subject to intense processes in industries including mining, power plants, quarries and mills.

Work Time: 30-60 minutes

Functional Cure: 8-12 hours

Max Service Temp: 120ºC

Ceramic Supergrade Epoxy Paste

Silicone carbide-filled epoxy paste which forms an ultra-smooth, low friction material highly resistant to abrasion. It rebuilds existing parts damaged by wear and is applied to new equipment to create a hardened protective shell, extending the lifespan of machinery.

Work Time: 60 minutes

Functional Cure: 90 minutes

Max Service Temp: 130ºC