Case Study: Leaking Welded Saddle Joint Repair on 150mm Steel Pipe at Pumping House

Saddle up for a complex repair – sealing a welded saddle joint with a 20mm step using Wrap & Seal

A 150mm steel pipe connected to a pumping house in Malaysia which was leaking from both ends of a welded saddle joint is sealed in a successful repair built up and over a 20mm step between the line and the joint.

Case Study Data

Site

Pumping house

Location

Malaysia

Repair Type

Live leak repair

Defect

Leaking saddle joint on a 150mm steel pipe with a 20mm step

Products Used

Wrap & Seal Pipe Burst Tape

Self-amalgamating silicone repair tape which sealed up and over the leaking saddle joint weld

Case Study PDF

Case Study Details

The 150mm steel pipe ran water out of the pumping house. The saddle joint had been welded in place to reinforce a capped tee and sat approximately 20mm higher than the original line. One end of the joint was suffering from heavy corrosion.

Water had been found seeping from both ends of the joint, leaving the pipe surface noticeably wet and the ground beneath the pipe sodden. The pipe could not be isolated or replaced because this would involve shutting down the pumping station.

Several repair attempts had been made using different methods by the water company operating the facility, including the use of a clamp and epoxy putty, but none had been successful. The pipe had therefore been left to leak.

Whilst on a visit to Malaysia, a technician from Sylmasta was asked to accompany a engineering team to inspect the pipe and see if a solution could be formulated. They recommended using Wrap & Seal Pipe Burst Tape to start a repair on the original steel pipe and build it up and over the weld, encompassing and sealing either end of the saddle joint.

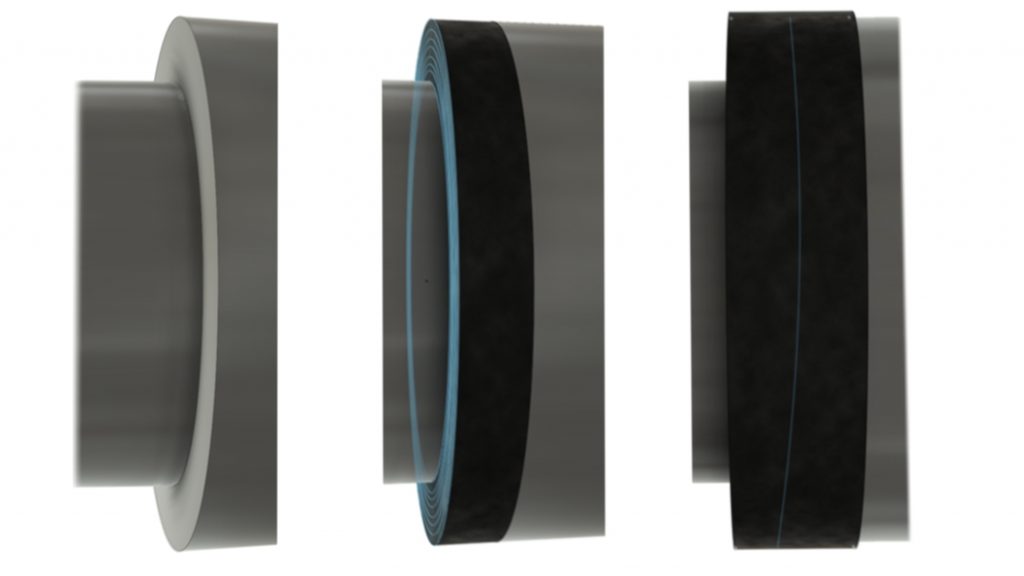

First, an angle grinder was used to sand down the pipe, clean it of loose material and remove corrosion. A first Wrap & Seal Tape was then applied directly next to the step. Wrap & Seal is made from self-amalgamating silicone and stretches by three times its length, fusing together to form a solid rubber band.

With each rotation, the Tape moved closer to being level with the top of the saddle joint. The application continued until enough Wrap & Seal had been applied to bridge the 20mm step between the pipe and the saddle.

Once this had been achieved, Wrap & Seal was applied 50mm across the saddle to achieve a good connection. It was then returned to directly over the edge of the joint.

Here, a ridge was created directly over the leak area to increase the pressure resistance of the repair. It was estimated that three Wrap & Seal Tapes needed to be used to seal one end, after which the process was repeated at the other end of the saddle joint.

Because the welded saddle joint had been seeping water slowly, the only way to check whether the application had been effective was to inspect several days later. When the pipe surface was found to be dry, the repair was deemed a success.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com