Case Study: Repair of Underground Clay Drainage Pipe Cracked During Building Work

Accidental impact and ground movement during building work left an underground 100mm clay drainage pipe cracked in two places and requiring repair at a domestic property in the United Kingdom. The homeowner accessed the pipe and sealed the leak themselves using a SylWrap Standard Pipe Repair Kit.

Case Study Overview

Site Domestic property

Location United Kingdom

Repair Type No pressure pipe repair

Defect Two cracks in underground 100mm clay drainage pipe

Repair Products

Superfast Steel Epoxy Putty, SylWrap HD Pipe Repair Bandage,

SylWrap Standard Pipe Repair Kit

Case Study PDF

Case Study Details

Clay was a popular material for drainage pipes in the United Kingdom from the early 20th century until the 1970s, when plastic became more widely used due to being easier and cheaper to fabricate and install.

High resistance to corrosion and chemical degradation gives clay extreme durability and longevity, with an estimated lifespan of anywhere between 60 and 100 years. This means many UK homes built before the 1970s are still serviced by working clay pipes.

One weakness of clay pipes, however, is they are susceptible to damage from root ingress and ground movement – which often only becomes obvious when a patch of ground becomes noticeably waterlogged from an underground leak.

A homeowner was carrying out building works when an area of their garden began suffering from this problem. After digging down, they discovered a dislodged 100mm clay pipe with two areas of significant damage.

The first and most severe was a crack next to a junction almost splitting the pipe into separate parts. The junction and uneven surface meant it would not be possible to reassemble the pipe using a repair clamp.

Across the top of the pipe was a hairline crack, representing the second damaged area. There was no pressure and the homeowner was keen to avoid the cost and disruption which would come with replacing the pipe.

They therefore used a SYL-412-NP SylWrap Standard Pipe Repair Kit to seal the leaks and attach the pipe back together. Before the repair, enough room was dug out underneath the pipe to allow clearance for it to be wrapped.

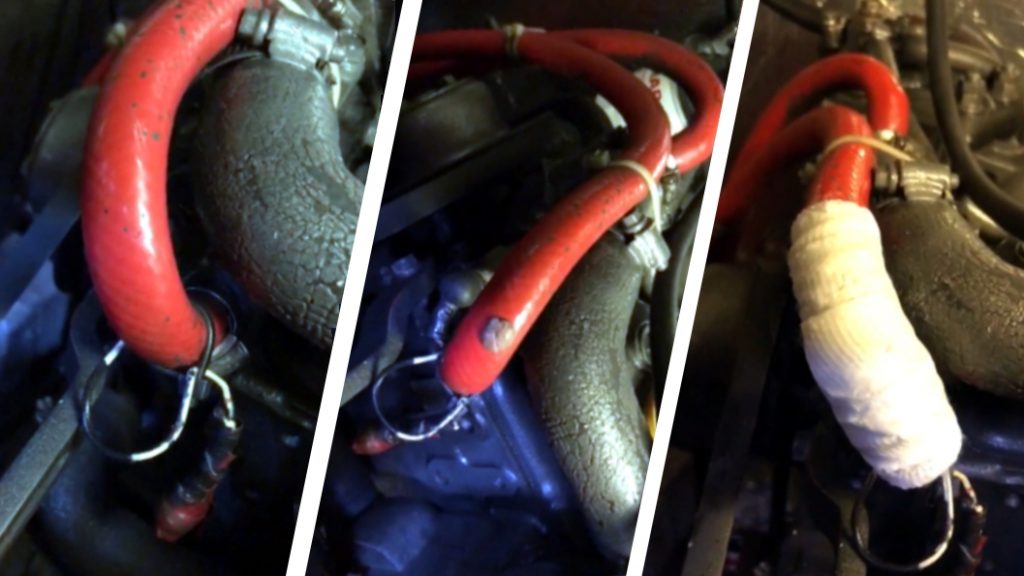

The two cracks were then filled with Superfast Steel Epoxy Putty. Enough putty was first mixed by hand to cover the hairline crack. It was then pushed firmly down across the top of the pipe, curing within five minutes to form a rock hard material covering the leak.

For the larger crack, more putty was mixed and forced into the gap between the two sections of pipe. Once it had set, Superfast Steel bridged the crack with a watertight material bonded to both pieces.

The pipe was then overwrapped with SylWrap HD Pipe Repair Bandage. The fast-working resin in SylWrap HD was activated with water and the bandage wrapped along the entire length of the exposed pipe.

SylWrap HD cured to form a rock-hard, impact resistant protective shell. It reinforced the repair and helped hold the two broken pieces of clay pipe back together.

The homeowner said afterwards that the repair worked perfectly and that the product was great. Completing the repair took under 30 minutes and cost less than £50, representing a huge saving compared with removing the pipe and installing a replacement.

With many clay pipes installed before the 1970s now beginning to reach the end of their natural lifespan, repairs such as this are set to become more common in the UK over the coming years.

Products Used

Superfast Steel

Fast working steel epoxy putty sets rock hard inside cracks and holes to seal leaks

SylWrap HD Bandage

Water-activated wrap reinforced the repair and helped hold the pipe back together

Standard Pipe Repair Kit

Kit containing Superfast Steel and SylWrap HD for permanent offline pipe repair

Related Case Studies

Case Study: Burst Copper Pipe Repair in Portable Horse & Dog Shower Unit

Case Study: Boat Owner Repairs Pinhole Leak in Rubber Hose Connected to Engine

Case Study: Leaking Hydrogen Line Pipe Repair at Power Station in Puerto Rico

Case Study: Repair of a Leaking 150mm Steel 90 Degree Elbow Bend at a Quarry Wash Plant

Case Study: Repair of a Cracked 90-year-old 70mm Malleable Iron Water Supply Pipe

Case Study: Repair of a Cracked Copper Pipe in a Camper Van Boiler System

If you have an application you would like to enquire about, please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com