Case Study: Repair of Corroded Domestic Water Main Pipe Embedded With Stones

A homeowner undertakes a DIY repair and refurbishment of a 2-metre section of heavily corroded, stone embedded domestic water main supply pipe. The surface damage was serious enough to have breached the metalwork, leaving the pipe leaking from various places underneath the driveway of the property.

Case Study Overview

Site Domestic property

Location Devon, UK

Repair Type Leak repair and pipe reinforcement

Defect Water main supply pipe damaged by corrosion and embedded with stones

Repair Products

Superfast Aqua PW Epoxy Putty, Liquid Metal Epoxy Coating,

SylWrap HD Pipe Repair Bandage

Case Study PDF

Case Study Details

Abnormal levels of water use alerted the homeowner to a potential leak somewhere in their supply system. The problem was soon identified to be underneath the front driveway.

Because the leak was in the pipe between the property and the external stop tap connected to the public supply, repair was the responsibility of the homeowner and not their water supplier.

The homeowner excavated the pipe and discovered it to be heavily corroded. Stones were embedded deeply at various points across the entire 2-metre line, the metal had been breached and it was leaking in multiple places.

Sealing the leaks would therefore not be enough; the homeowner needed to strengthen the pipe to prevent further damage in the future, before it was reburied under the drive.

Water supply was turned off at the external stop tap and the system drained before the domestic water main pipe repair began. The homeowner then set about thoroughly cleaning the pipe as much as possible.

This involved removing dirt, followed by surface corrosion. Next came the challenge of the stones, some of which were embedded so deep into the pipe as to effectively be welded to the metal.

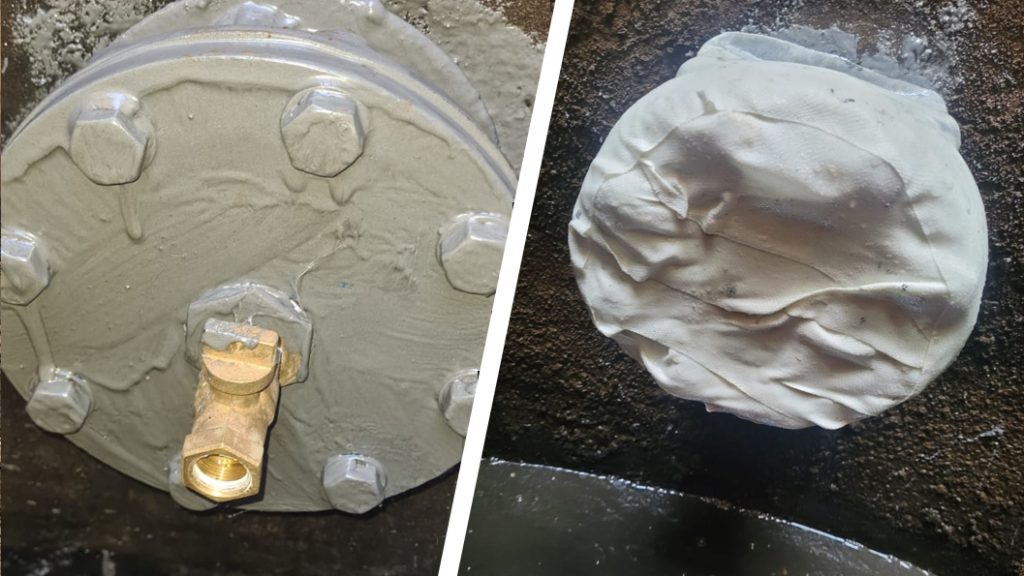

Many of the stones therefore left craters and severe surface damage in the pipe following their removal. These and the other leak areas identified after excavation were repaired with Superfast Aqua PW Epoxy Putty.

Superfast Aqua PW was chosen for its excellent wet surface adhesion; compensating for the possibility some water may have been left behind when the pipe was drained and could seep from the pipe during repair.

It also has WRAS Approval, meaning it is safe to use on pipes and fittings carrying drinking water. This was an important consideration with the main bringing supplies from the public water network into the property.

The putty was kneaded by hand until it turned a uniform white colour. Whilst still soft, it was pushed into all leak holes and craters in the pipe. Within 20 minutes, Superfast Aqua PW had cured to a solid material, filling all damage.

Liquid Metal Epoxy Coating was then used to reinforce and refurbish the brittle steel. The homeowner painted 1kg of Liquid Metal in two coatings over the entire pipe and all joints. It set to form a new smooth, metallic, hard-wearing outer surface as a shield against corrosion.

Further reinforcement was provided by SylWrap HD Pipe Repair Bandage. SylWrap is a composite wrap with a water-activated resin which sets rock-hard in minutes.

Three SYL309HD Bandages were wrapped across the entire 2-metre section, including around a 90-degree elbow and another difficult geometry where the pipe began to climb up a wall.

The application of SylWrap began whilst the final coating of Liquid Metal remained slightly tacky, improving adhesion between the bandage and the pipe surface.

Once cured, SylWrap provided an impact-resistant sleeve around the pipe to complete the repair by preventing the line becoming stone embedded again in future.

The homeowner completed the repair over a weekend; one day for cleaning the pipe, removing debris and sealing holes. The second day for the application of Liquid Metal and SylWrap HD Bandage.

Water supply was turned back on to test the main. The combination of Superfast Aqua PW, Liquid Metal and SylWrap HD easily contained pipe content, as well as offering robust protection and a fully refurbished line. The pipe was then reburied.

Products Used

Superfast Aqua PW

WRAS approved epoxy putty with excellent wet surface adhesion for sealing pipes

Liquid Metal

Brush applied coating creates a metallic shell over pipework to protect against corrosion

SylWrap HD Bandage

Composite wrap with water activated resin encompasses pipe with rock hard shell

Related Case Studies

Case Study: Corroded & Leaking Worthington-Simpson Pump Head Repair

Case Study: Heat Exchanger Water Box Corrosion Protection at Power Plant

Case Study: Corroded 30-Metre Section of Sewer Force Main In Underground Vault Repair

Case Study: Luxury Portable Toilet Trailer Leaking Wastewater Holding Tank Repair

Case Study: Repair of Leaking & Corroded Shared Water Supply Pipe Connected to Eight Cottages

Case Study: Corrosion Protection of 600mm Ductile Pipe & Outlets in Underground Pumping Station

Case Study: 3 Metre Section of Corroded Steel Gas Pipe in CHP System Repair & Refurbishment

Case Study: Capped Pipe Encapsulation in Decommissioned Landfill Drainage System Landfill

Case Study: Permanent Anti Slip Solution to Protect Workers When Standing on Helicopter Skids

If you have an application you would like to enquire about, please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com