Case Study: Dairy Delivery Truck 466 International Engine Cracked Timing Cover Repair

Replacing a delivery truck’s 466 International engine timing cover after it developed a hairline crack was set to cost a milk company in Puerto Rico $1000 until Sylmasta formulated a faster, more cost-effective repair method. The crack was filled with Industrial Metal Epoxy Paste and the vehicle back on the road within 24 hours.

Case Study Overview

Site Dairy

Location Puerto Rico

Repair Type Truck engine timing cover repair

Defect Hairline crack leaking oil in 466 International engine timing cover

Repair Products

Industrial Metal Epoxy Paste

Case Study PDF

Case Study Details

The delivery truck belonged to a milk company in Puerto Rico. Oil was discovered to be leaking from the timing cover of the vehicle’s 466 International engine. Once opened, a hairline crack was discovered in the casing.

A replacement cover would have cost $1000. Delivery of the part was estimated to take up to a week. The company needed the truck to be back in service as soon as possible and so they sought a faster, more cost-effective repair.

Sylmasta technicians were able to formulate a repair method for the timing cover, involving a degree of preparation followed by the use of Industrial Metal Epoxy Paste. Instructions were sent to the engineer, who had been asked to find a solution by the company.

Before the application of the paste began, Sylmasta recommended that the ends of the crack were drilled. This was to relieve stress concentration and prevent the crack from spreading further.

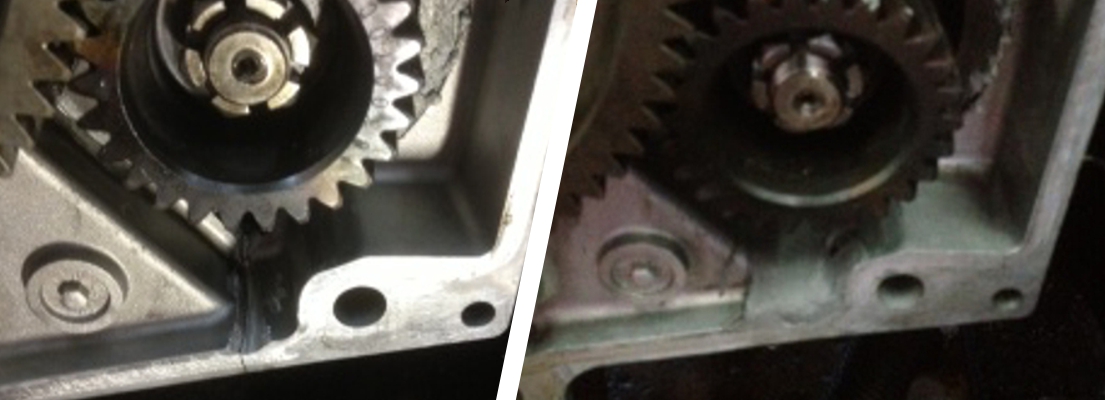

A coarse 3-square file was used to cut a V-shaped groove along the length of the crack, widening the gap in both the top of the metalwork and underneath. This increased the available surface area to which Industrial Metal could bond. The V-grooves were then degreased to remove contamination.

Part A and Part B of Industrial Metal were mixed in the instructed ratio. A spatula was used to force the paste into the crack, completely filling both V-grooves. The paste was also overlapped by 20mm either side of the crack to ensure full adhesion.

Industrial Metal has a work time of 60 minutes, allowing it to be carefully applied to the crack without needing to worry about premature curing. A full cure was achieved in 24 hours, after which the paste set to form a solid metallic material which seamlessly filled and repaired the crack.

One day after the repair had been completed, the delivery truck was back on the road with the 466 International engine no longer leaking. The company were very pleased with the technical advice offered by Sylmasta, and the speed and ease with which they had been able to complete the application.

Products Used

Industrial Metal

Epoxy paste used to repair and rebuild damaged metalwork and equipment

Related Case Studies

Case Study: SylWrap Composite Pipe Repair Passes ASME PCC-2 401-III Qualification Standard

Case Study: Corroded 30-Metre Section of Sewer Force Main In Underground Vault Repair

Case Study: Reinforcement of Weakened Pipe Elbow Joint on 100mm 22 bar Sulphuric Acid Line

Case Study: Industrial Metal Repairs a Large Gouge to Refurbish a Drill Base Stand

If you have an application you would like to enquire about, please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com